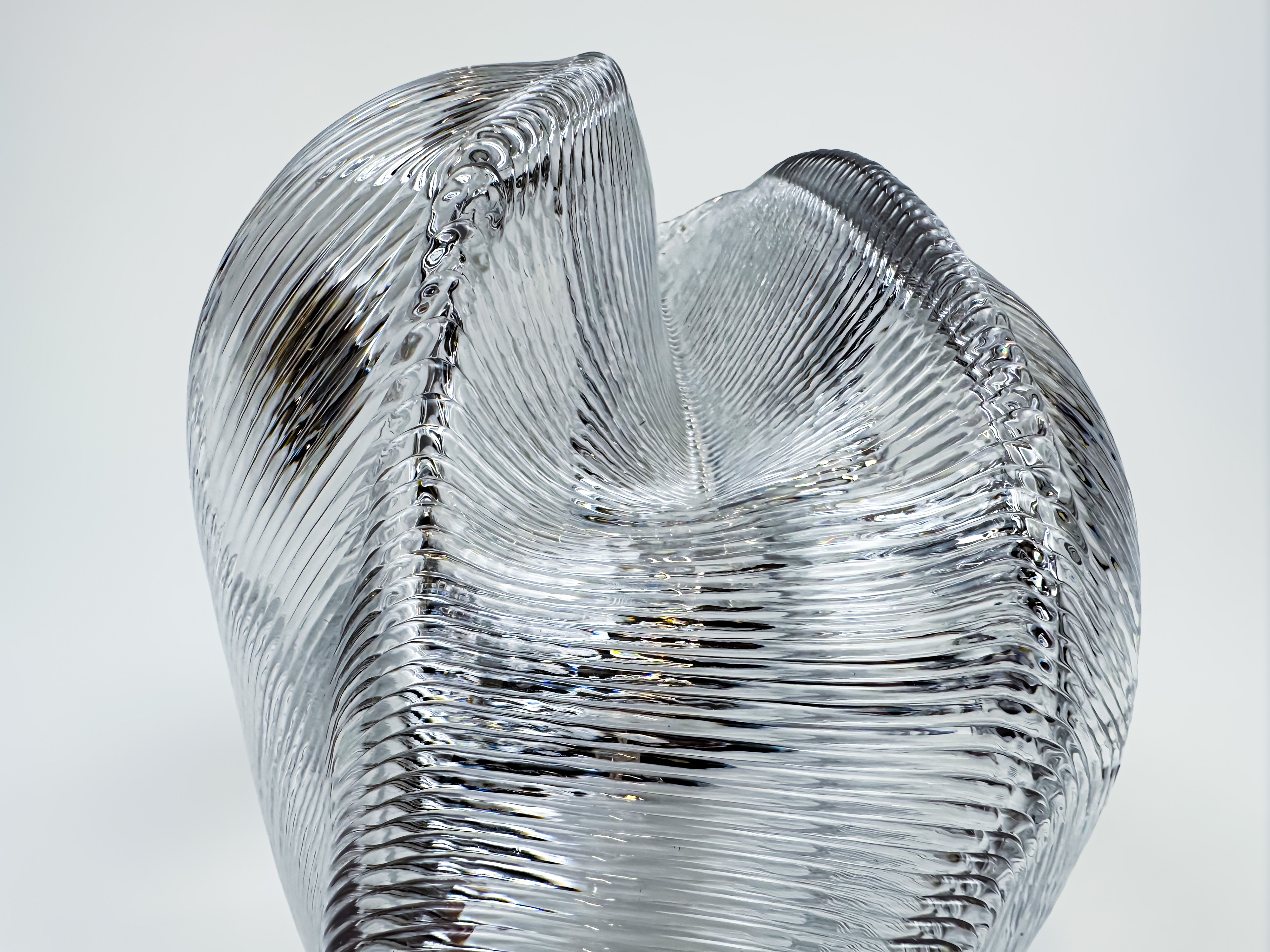

Mold-less blowforming of architectural thermoplastics could enable lightweight structures, material savings, efficient prefabrication means, and on-site adaptive assembly, while introducing rich and non-prescriptive shape transformations. However, shaping control demands real-time responsiveness and flexibility which is lacking in traditional mold-based and artisanal shaping methods.

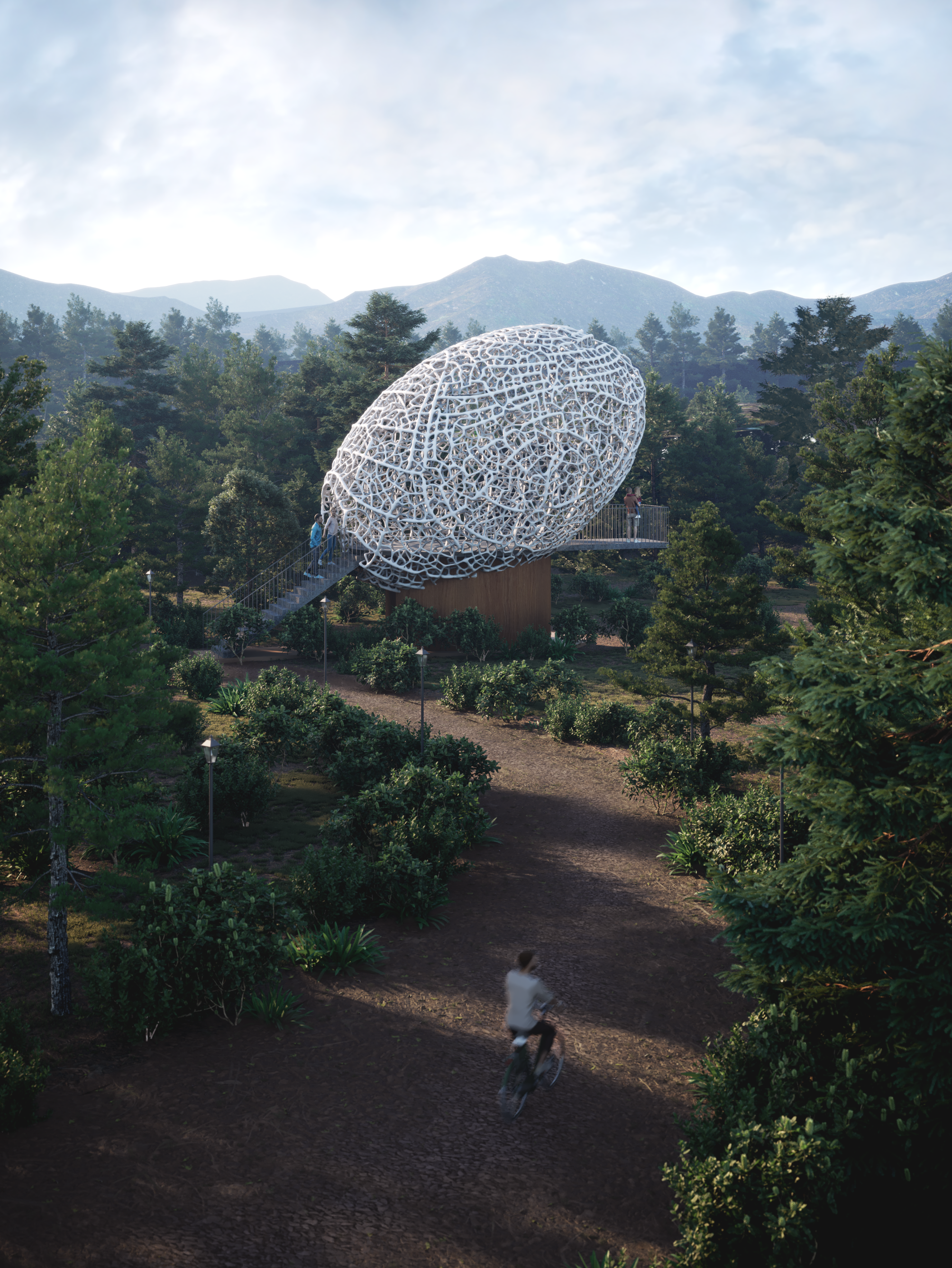

To overcome these limitations, this research introduces a workflow for mold-free robotic blowforming and recursively aggregating hollow thermoplastic components made from Fused Granular Fabrication (FGF)-printed polyethylene terephthalate glycol (PETG). Similar preforms undergo different inflation behaviors by responsive blowforming in our methodology transforming into components that can be recursively assembled into architectural-scale systems such as partitions, arches, or vaults, adapting on-site to variable orientation, density, and configuration to their local context.

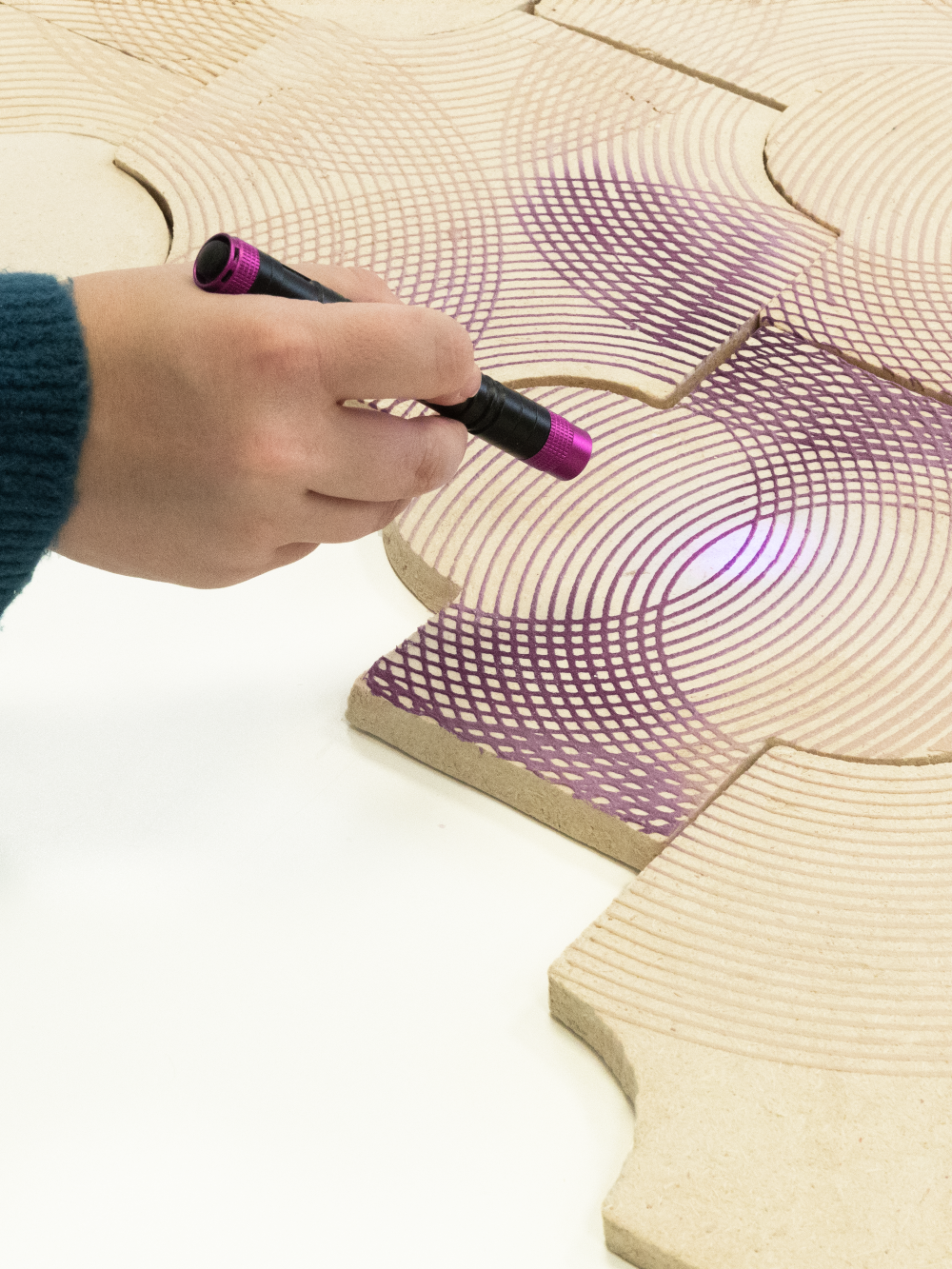

The virtual workflow integrates physics-based inflation simulation, depth sensing for robotic pick-and-place operations, and thermal feedback for real-time toolpath adaptation during localized heating. In our integrated fabrication a custom robotic end-effector, equipped with pneumatic inflation, adaptive gripping, and a depth-sensing technology, autonomously handles preforms for local heating before final adaptive inflation and precise spatial placement.

This feedback-driven fabrication approach reduces dependency on heavy, expensive, and rigid molds as well as in analog human intervention, presenting a scalable and automated alternative to conventional prefabrication. Results demonstrate predictable deformation outcomes, efficient recursive aggregation, minimal material waste through targeted heating, and rapid, scalable production. By enabling real-time customization and responsive assembly, the work advances robotic-assisted architectural fabrication, offering significant potential for real-time customization and responsive spatial assembly.

The setup uses two independent air lines: one delivers a steady 10 psi to the SMC-MHL2 parallel gripper for securely holding 3D-printed parts, while the other manages inflation with a digitally controlled pressure range of 1–10 psi via an Arduino-connected regulator for precise blow-forming.

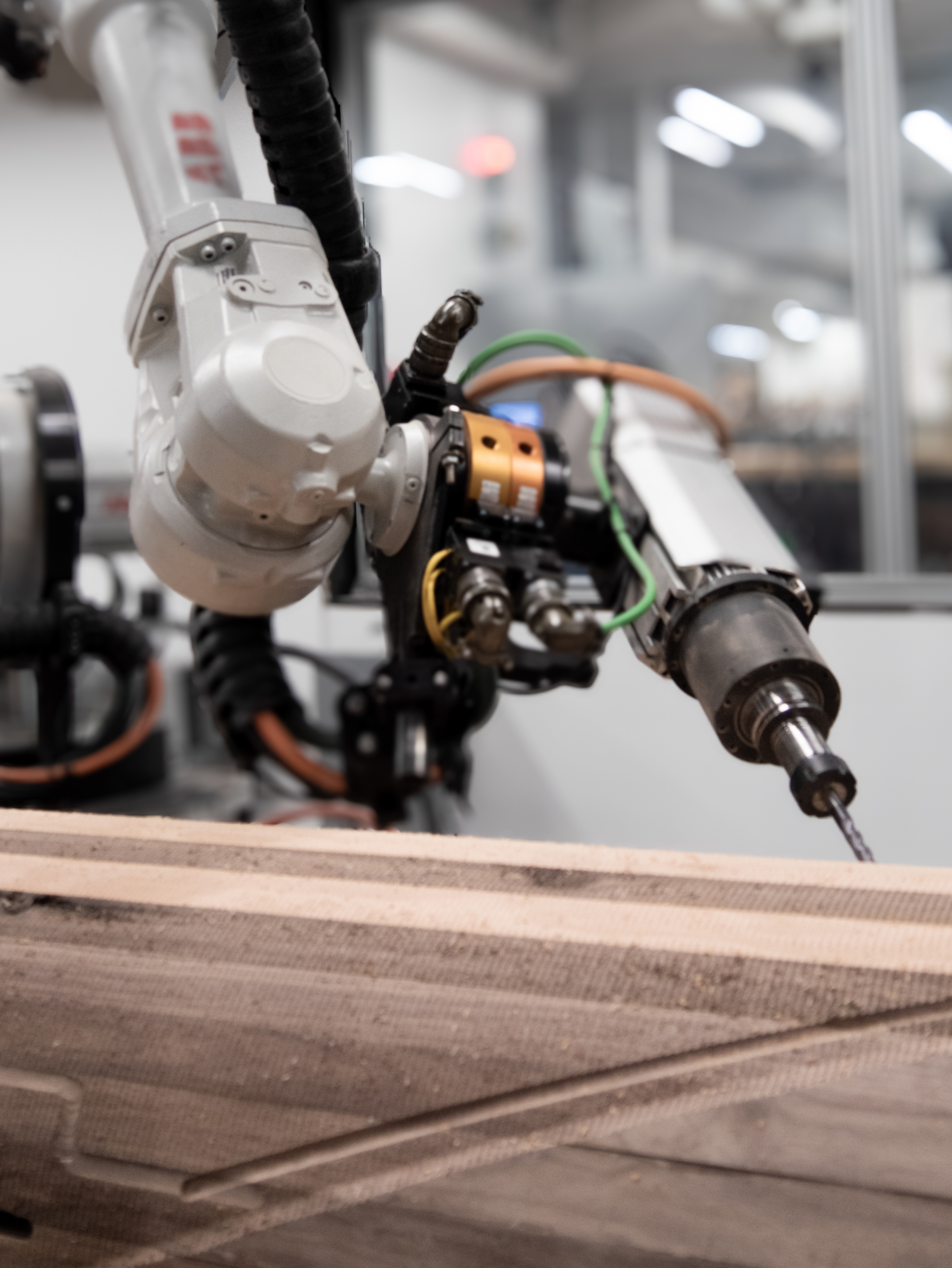

The customized finger design features a notch that interlocks with the desktop-printed preform, securing it during robotic movement. A ¼” metal airline pipe is mounted alongside the gripper for inflation. An Intel RealSense LiDAR L515 Camera, aligned with the tool’s TCP, scans the preform and imports point cloud data into Grasshopper through the RADii Capture plug-in. The data is processed by Z-value sorting to detect and localize the preform geometry.

The robotic system is composed of the following interconnecting modules : (1) heating station, (2) assembly station, (3) air control station, (4) robot control center, and (5) wire and piping system.

The heating station is composed of a heat gun, a thermal camera, a webcam, a robot arm, and a gripper. The goal is to execute precise heating behavior on 3d printed PETG pieces, ensuring repetitiveness and precision in localized inflation behaviors.

The assembly station is composed of a robot arm and a customized end-effector, which includes a real sense depth camera, a gripper with a customized head, and an air pipe. The integrated end-effector would allow the robot to automate the pick and place process, realize accurate positioning, and assemble aligned with digital design.

The air control station is composed of two sets of control systems, one for the gripper and one for inflation. Each of them requires a different pressure range, control accuracy, and control method.

The Robot control center is composed of a robot pendant and a robot controller, which allows direct operation through the control panel. This provides an alternative method to control customized tools without relying on a computer interface and programming.

There are 3 distinct sets of wire and pipe systems. One for information communication(marked in red), one for air pipelines(marked in blue), and one for power supply(marked in black, which includes electrical power and air source.

Master of Science in Design: Robotics and Autonomous Systems (MSD-RAS)

Weiztman School of Design, University of Pennsylvania

ARCH 802 Material Agencies III_ Spring Semester

Instructors: Robert Stuart-Smith & Nathan King & Laia Mogas-Soldevila & Jeffrey Anderson

TAs: Mahsa Masalegoo & Franklin Wu

MSD-RAS Program Director: Robert Stuart-Smith

ARI Robotics Lab Operators: Nicholas Sideropoulos & Shunta Moriuchi

Team Lobster: BurcuGocen, BeikelRivas, QingyangXu, ZitongRen